Recupero de subproductos

Comúnmente, en los procesos de producción de alimento para mascotas, se generan subproductos secos y húmedos, con diferentes características en cuanto a parámetros fisicoquímicos.

La mayoría de los finos provienen de zarandas, secadores, enfriadores, ciclones, transportes; con bajos contenidos de humedad y variabilidad en la temperatura. Otro subproducto seco, que se considera merma, es el producto final de rechazo o defectuoso, el cual no cumple los estándares de calidad para ser entregado al cliente final.

Por otro lado, los subproductos húmedos se originan en las paradas y arranques de extrusores. Dado su alto contenido de humedad, estos subproductos suelen ser muy complicados de tratar ya que tienen una rápida descomposición y generalmente se presentan en forma de grumos pegajosos.

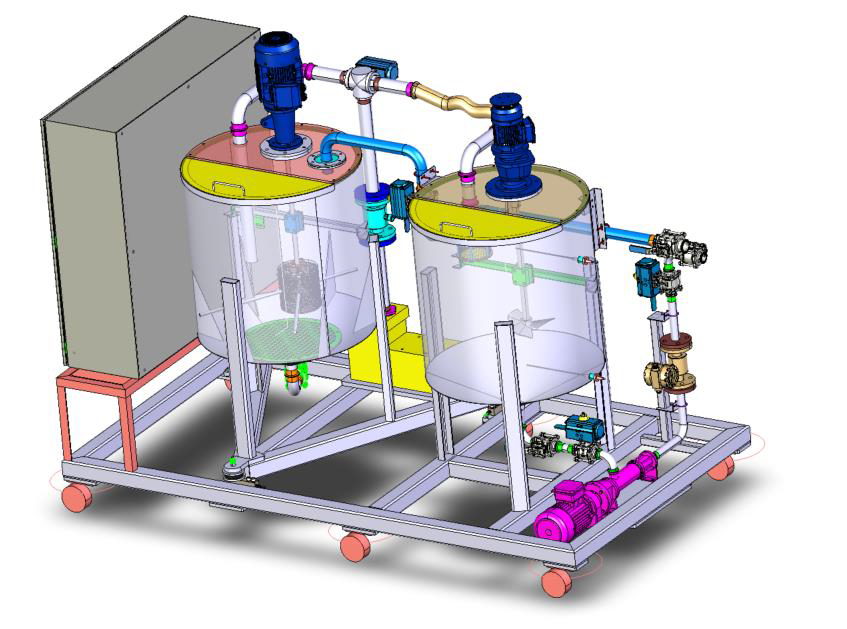

El Sistema de Recupero de Subproductos (SRS) recupera los sólidos generados en cualquier parte del proceso, aprovechando así al máximo los productos y el tiempo de producción. El recupero de subproductos se realiza de forma rápida, no dando tiempo a la descomposición de la materia, principalmente cuando se trata de subproductos húmedos de arranques y paradas de extrusor.

Sus ventajas más importantes:

- Aprovecha el 99,9% de los subproductos.

- Ahorra costos y tiempos de reprocesos.

- Optimiza el proceso de fabricación.

- Mejora la trazabilidad.

- Se obtiene un slurry sumamente homogéneo.

- Es de fácil limpieza.

- Posibilidad de instalación horizontal o vertical.

La adición de slurry reemplaza parte del agregado de agua en el preacondicionador, por lo que es necesario que este proceso se realice de manera controlada mediante señales electrónicas, ya que continuamente se debe monitorear la cantidad de agua que ingresa al preacodincionador/extrusor de manera directa, y la cantidad que ingresa a través del SRS. Este sistema de control vuelve el proceso completamente automático, con un mínimo de intervención humana.

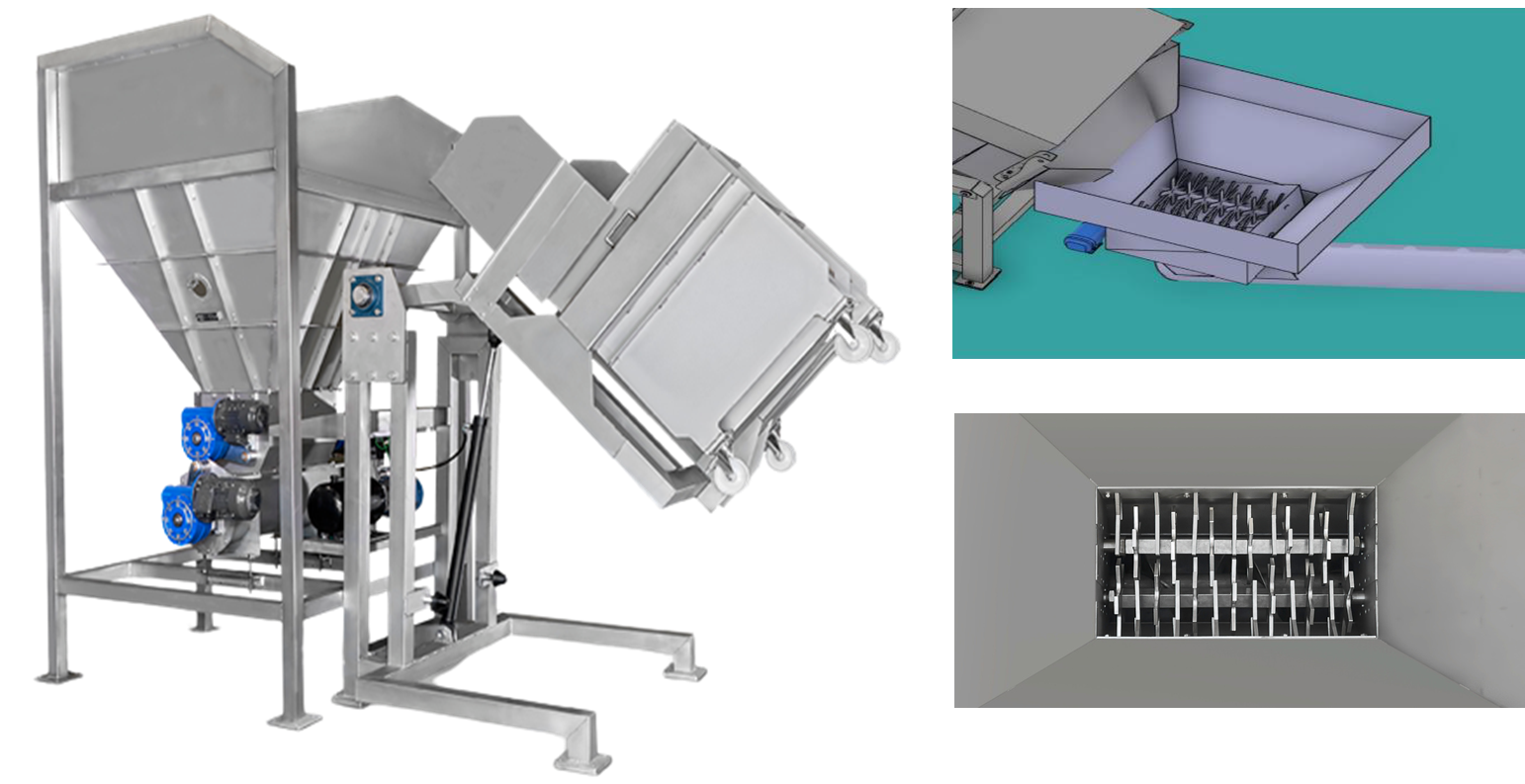

Con el SRS no solo podremos recuperar los subproductos generados durante todo el proceso, sino que también tendremos la posibilidad de adicionar carne fresca para lograr recetas super premium. El sistema puede adaptarse fácilmente para adicionar carne emulsionada o, incluso, podemos brindar una solución completa para procesar carne fresca y/o congelada, transformándola en una emulsión que pueda ser inyectada de manera controlada.

En los proyectos más integrales, se incluye:

- Recepción de carne fresca y/o congelada

- Cutter o triturador

- Tolva de almacenamiento intermedio

- Mezclador con emulsificador

- SRS modificado para inyectar subproductos + carne emulsionada.

.jpg)