.jpg)

¿Conoces cuáles son los beneficios de contar con un SRS?

Gran parte de las empresas se enfrentan al desafío de lidiar con reprocesos que oscilan entre el 3% y el 5%. Estos reprocesos pueden ser tanto subproductos secos provenientes de zarandas, secadores, enfriadores y transportes neumáticos, como desechos húmedos generados durante los ciclos de parada y arranque de extrusores.

La práctica tradicional para reutilizar estos subproductos secos implica su retorno a la etapa de dosificación, lo que conlleva un aumento en los costos operativos, un desgaste prematuro de piezas críticas, una disminución de la capacidad de producción y la necesidad de reprocesar un material que ya ha sido sometido a procesamiento previo.

Por otro lado, los desechos húmedos generados en las fases de parada y arranque del extrusor a menudo se venden como productos de baja calidad destinados a la alimentación porcina. Si estos subproductos no se tratan rápidamente, proliferan bacterias, moscas y malos olores, afectando la sanidad de la planta.

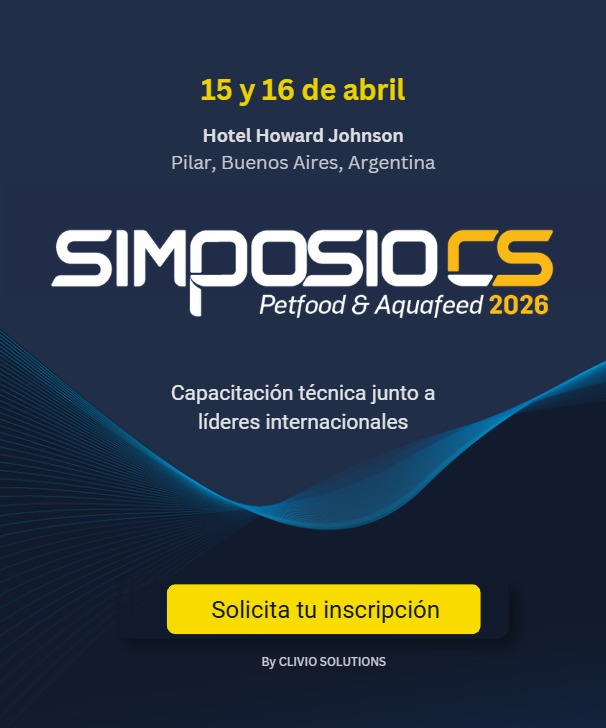

En este contexto, Clivio Solutions y SATI presentan la solución confiable, eficiente, automática e innovadora a este problema recurrente: el Sistema de Recupero de Subproductos, o SRS.

¿Cuáles beneficios clave se obtienen al adquirir este equipo?

- Mejora de la eficiencia en el proceso de recuperación, lo que contribuye a la sostenibilidad de la organización.

- Transformación de todos los subproductos en productos terminados, evitando la venta de productos de baja calidad destinados comúnmente a la alimentación animal en granjas.

- Reducción del consumo de energía y, por ende, de los costos operativos.

- Liberación de capacidad de producción.

- Eliminación de la necesidad de volver a dosificar y procesar nuevamente un producto ya tratado.

- Automatización del proceso de recuperación.