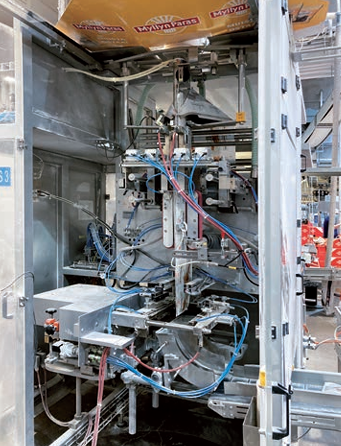

Envasado VFFS

Junto a Rovema ofrecemos envasadoras verticales continuas (VFFS), equipadas con sistemas de alta calidad que ofrecen grandes resultados en el proceso de envasado. La aplicación de estos sistemas es para tamaños pequeños de bolsas (hasta 10-11 kg con un ancho maximo de 400 mm en la bolsa).

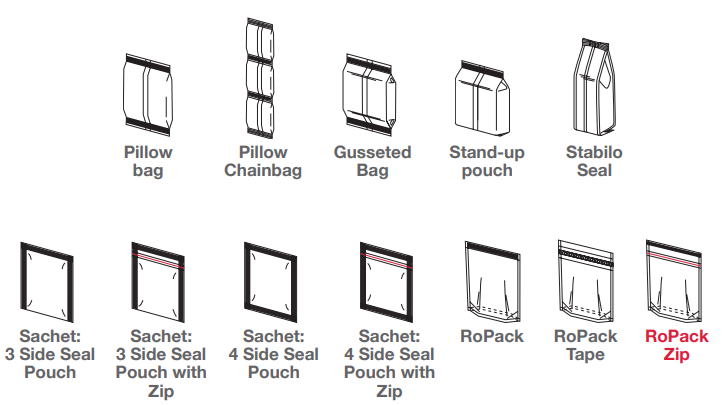

Algunos de los tipos de bolsas que puede trabajar son:

Las maquinas VFFS se encargan de formar, llenar y sellar el paquete partiendo de una bobina plana de film, siguiendo el principio que vemos a continuación:

Destancan como ventajas:

- Máquina contínua, no intermitente, lo que permite mayores capacidades.

- Presión de sellado programable desde la pantalla (estándar 5000 N, opción hasta 8000 N).

- Detección de producto entre mordazas (Sense & Seal).

- Seguimiento automático de la película de film.

- Cintas de arrastre de película asistidas por vacío.

- Control de presión de sellado (Premium Seal).

- La eficiencia de máquina según DIN 8743 es del 98%.

- Perfecto sellado gracias al control por pantalla y reproducibilidad en la receta del producto de los 3 parámetros de sellado: tiempo, temperatura y fuerza.

En estrecha colaboración con muchos fabricantes de materiales de embalaje conocidos e innovadores, se prueban sistemáticamente nuevos materiales de embalaje alternativos para comprobar su compatibilidad con las máquinas Rovema, sus propiedades de sellado y sus parámetros de rendimiento. Con dicha pasión por las soluciones de envasado sostenibles, se ofrecen máquinas y equipos de envasado innovadores que protegen el medio ambiente y permiten un futuro más sostenible.