Microdosificación

Los sistemas de microdosificación de Jesma han sido especialmente desarrollados para la dosificación fina de ingredientes, aditivos y materias primas, donde una sobre-dosificación de micro ingredientes puede resultar costosa, y una sub-dosificación una deficiencia en el producto final.

Una condición para un producto final de alta calidad es una dosificación controlada y precisa de los ingredientes. Los sistemas de dosificación micro y nano dosificación están especialmente desarrollados para la dosificación precisa de ingredientes. En Jesma, cada sistema se adapta a los requisitos del cliente y, al tener en cuenta cuidadosamente las características del producto, hace posible una dosificación precisa incluso de productos con poca fluidez.

Con nuestra tecnología lograrás:

- Seguridad en el proceso.

- Evita el error humano de colocar un producto en el silo equivocado (sistema de apertura de silos mediante código de barras).

- Silos cilíndricos, por lo cual el producto no se pega en las esquinas y evitamos el rat holing.

- Raspador de fondo de silo, para garantizar un flujo continuo y libre, para todas las materias primas.

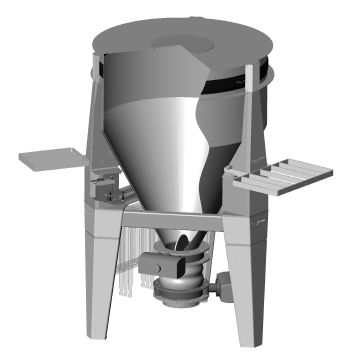

- Propeller y tapa neumática, para maximizar precisión y cortar el flujo en el momento exacto.

- Básculas ateflonadas y cilndricas, para una descarga completa y rápida.

- Sistema de filtrado para aspiración de polvo.

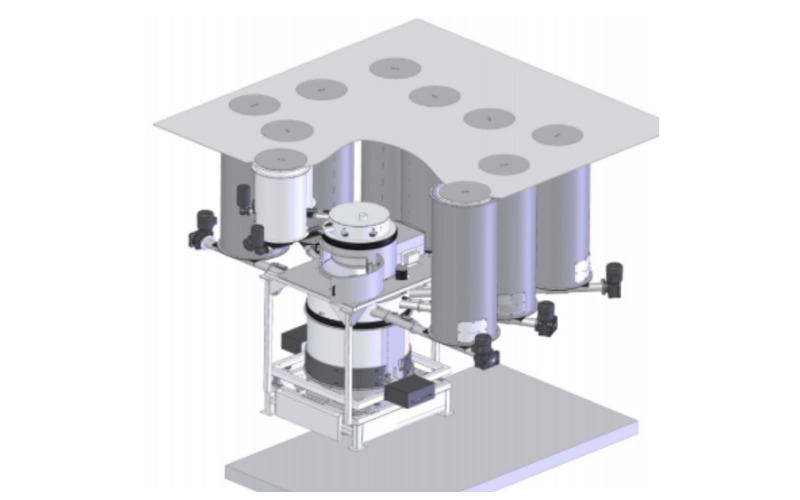

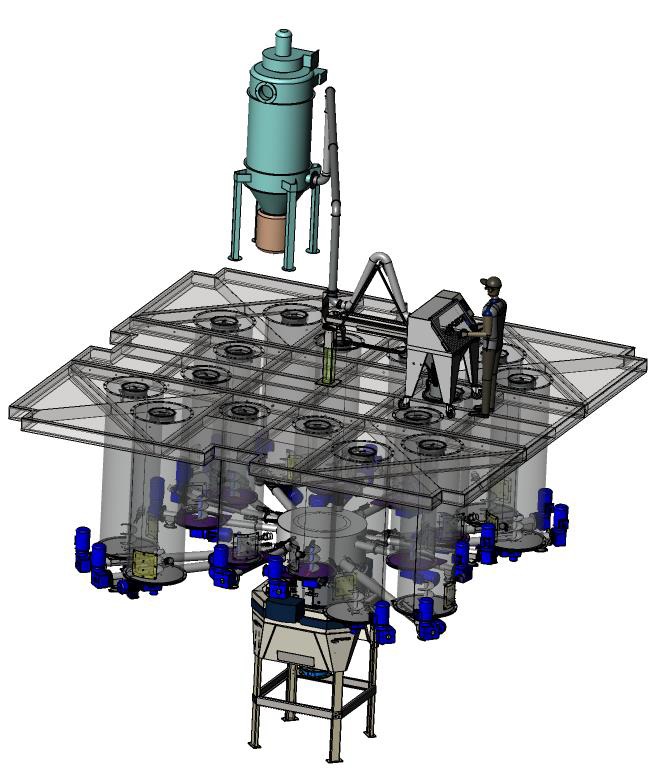

A continuación, una instalación con varios equipos de micro y nano dosificación instalados en Polonia.

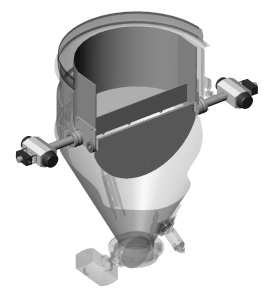

El sistema se puede disponer en forma de círculo, semi-círculo, cuadrada o la requerida, dependiendo del espacio disponible y de la ubicación. Jesma ofrece distintos tipos de microbásculas para el sistema de dosificación que se adaptan a las necesidades del cliente; cada una con un diseño que garantiza el vaciado completo del contenedor de pesaje. Los silos están disponibles con fondos vivos con rascadores y tornillo agitador, que garantizan el vaciado completo de los materiales con poca fluidez y un llenado uniforme del tornillo dosificador.

Balanzas de nano dosificación

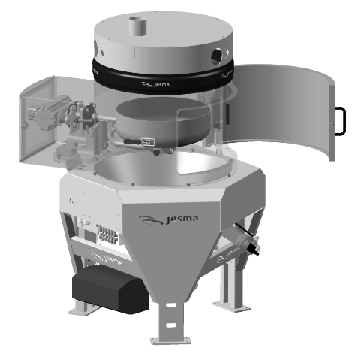

La báscula dosificadora JesBatch Nano está diseñada para eliminar la contaminación cruzada y funcionar con una precisión estática muy alta en la dosificación y pesaje de ingredientes en pequeñas cantidades. La báscula consta de un recipiente de pesaje recubierto de teflón que se vacía cuando se le da la vuelta neumáticamente y se hace vibrar con un martillo neumático para garantizar un vaciado completo entre lotes. Estas básculas van desde 2 kg (+/- 0.5 g) hasta 30 kg (+/- 7 g).

Balanzas de micro dosificación

La báscula JesBatch Micro consta de un recipiente de pesaje con aletas inferiores activadas neumáticamente para el vaciado. Las aletas están recubiertas de teflón y se abren 90° para garantizar un vaciado completo entre lotes. Estas básculas van desde 50 kg (+/- 10 g) hasta 200 kg (+/- 40 g).

Balanzas de medi dosificación

Jesma completa la gama de básculas dosificadoras con la JesBatch Medi para la dosificación de ingredientes de tamaño medio. Para evitar la acumulación de polvo en el entorno, debe existir una ligera presión negativa en la báscula, por lo que es necesaria la aspiración. Además, debe asegurarse de que el aire del sistema de transporte neumático inferior no afecte al pesaje, y esto se logra montando una válvula encima del sistema de transporte. Estas básculas van desde 400 kg (+/- 100 g) hasta 1000 kg (+/- 250 g).

Todas las básculas se suministran con el interior completamente liso para garantizar un vaciado óptimo y una contaminación cruzada mínima, combinado con una construcción resistente y rígida para lograr la mejor fiabilidad operativa posible.

.jpg)