Recepción en big bags

Muchas de las materias primas se reciben en big bags, y es un desafío poder realizar una descarga segura y automática del producto. Con los descargadores de Comav podrás volver este proceso mucho más eficiente y seguro.

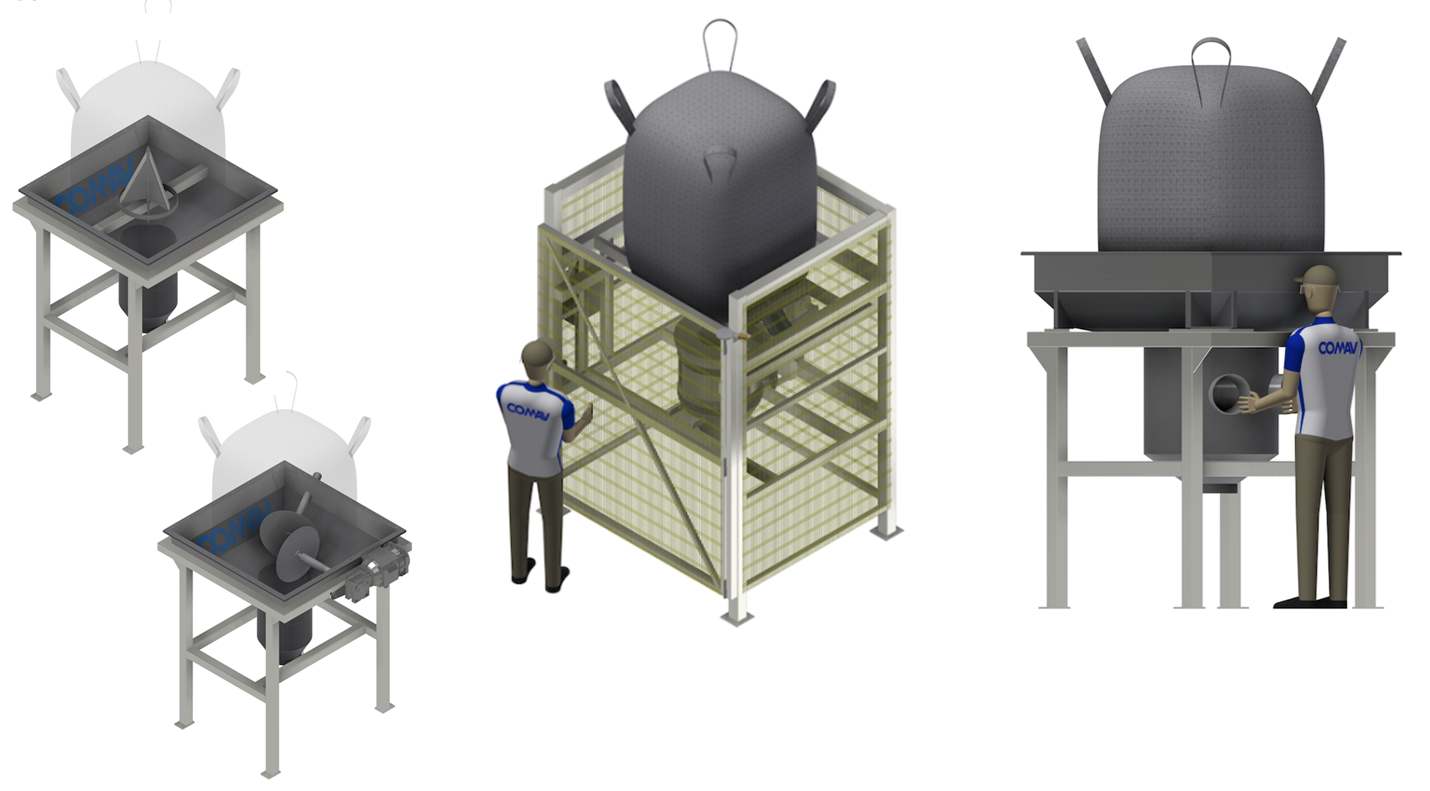

Si los big bags pueden desecharse, entonces las cuchillas de apertura se encargarán de hacer su trabajo y desgarrar el fondo del big bag. En cambio, si el big bag se reutiliza y en el fondo cuenta con una manga o cuello, entonces el equipo adecuado es aquel que permite al operario intervenir de manera manual para la apertura. En Clivio Solutions, junto a Comav, tenemos ambas opciones de apertura.

El equipo ideal para tu planta será aquel que se adecúe al nivel de automatización y la capacidad de descarga que quieras lograr, siempre priorizando la seguridad.

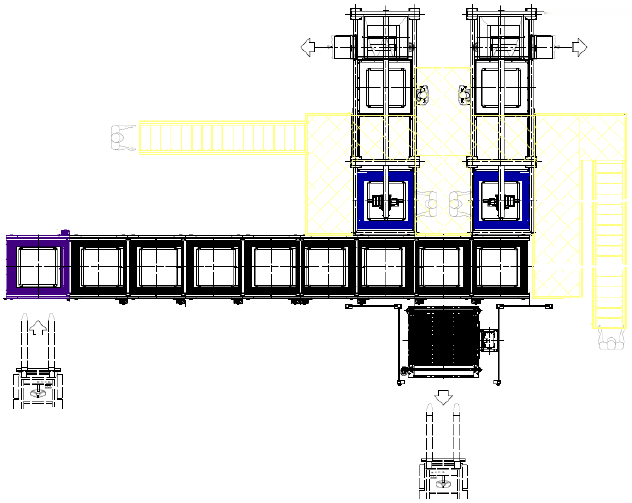

Cuando se requiere una capacidad de descarga elevada, entonces debemos recurrir a un conjunto de descargadores, que pueden trabajar en paralelo sin problema. Un ejemplo de instalaciones de este tipo se muestra a continuación, donde se utiliza el mismo canal de alimentación mediante rodillos transportadores para ambos sistemas de descarga.

Junto a Comav se ofrece una amplia gama de sistemas para apertura de big bags con y sin manga de descarga. Para estas aplicaciones, se encuentran disponibles múltiples accesorios como:

- Cilindros de vaciado remanente inferior del big bag.

- Polipastos con cable o a bateria (inalámbrico).

- Válvulas rotativas para transporte neumático u otro tipo de transporte.

- Válvulas de cuchilla para el cierre de la manga del big bag.

- Rompedores de grumos.

- Sistemas para la extracción y filtración de la polución generada, y su reinserción del polvo al sistema de transporte para maximizar el aprovechamiento.

- Los equipos disponen de una tolva plana con junta especial dotada de una estructura salvamanos útil para desenganchar la manga.