Macrodosificación

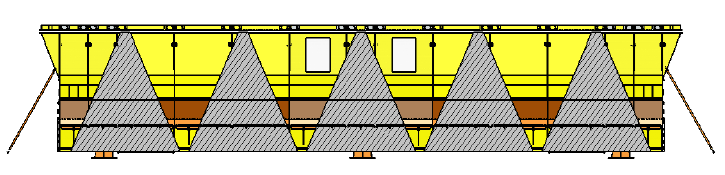

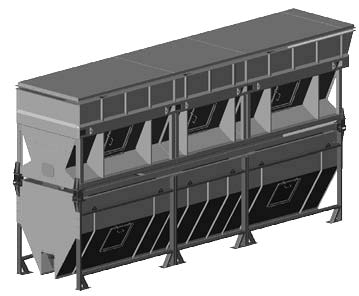

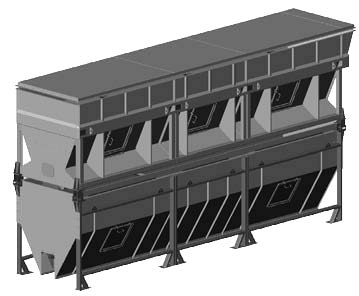

Las básculas de tolva simple y/o doble para macrodosificación están diseñadas y construidas para satisfacer la demanda con fiabilidad operativa óptima en las industrias de procesos modernas. Con la báscula JesHopper es posible dosificar lotes grandes. Las básculas de tolva están diseñadas para una alimentación y descarga rápida, precisa y fiable de materiales como cereales y harinas.

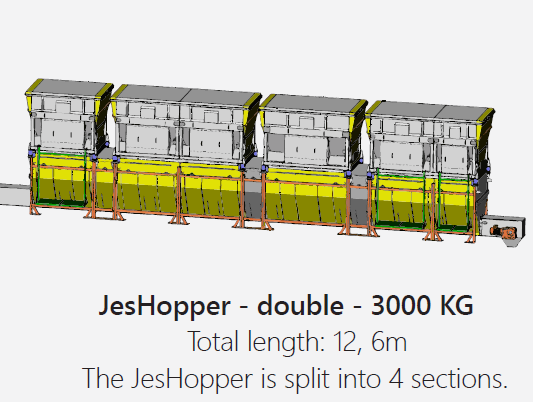

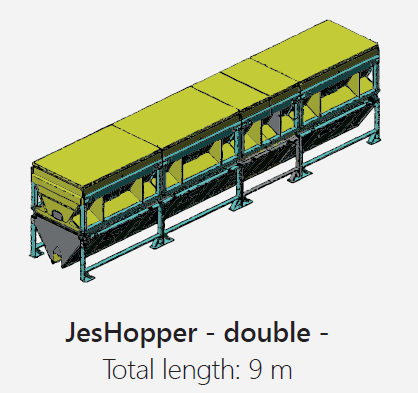

Todas las básculas de tolva de Jesma están diseñadas y suministradas con una construcción modular, lo que garantiza un transporte sencillo y un alto grado de flexibilidad, permitiendo ampliaciones sin necesidad de grandes reconstrucciones si fuera necesario en un futuro.

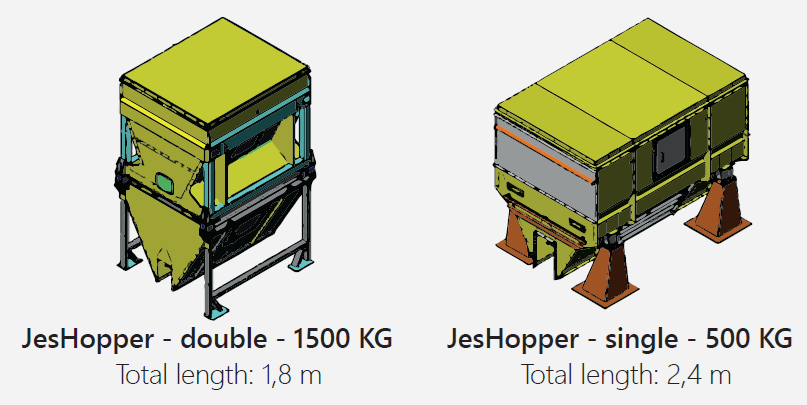

Nuestra gama estándar presenta un rango de capacidades de 200 kg hasta 10.000 kg.

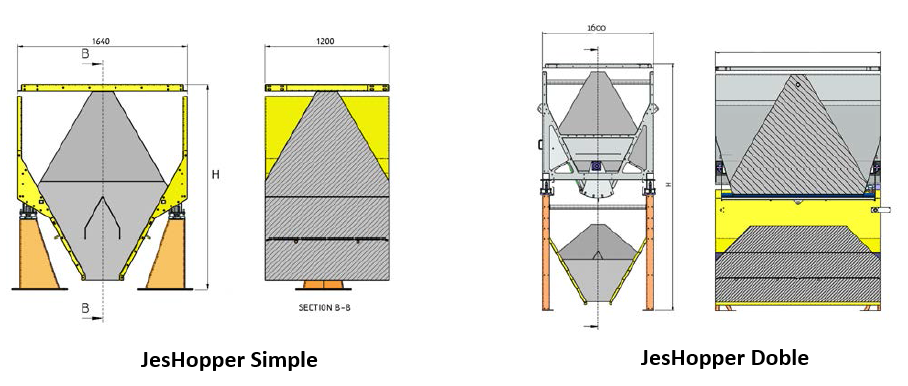

Básculas simples

Consta de una tolva de pesaje, celdas de carga, patas soportes y espacio para un transportador inferior. Aporta una gran flexibilidad y distintas posibilidades de ajuste. El material se llena mediante dispositivos de dosificación desde la parte superior, y cuando la báscula ha alcanzado la cantidad deseada de material/producto, la JesHopper Simple se vacía mediante el transportador de cadena situado en la parte inferior de la tolva de pesaje.

Báscula doble

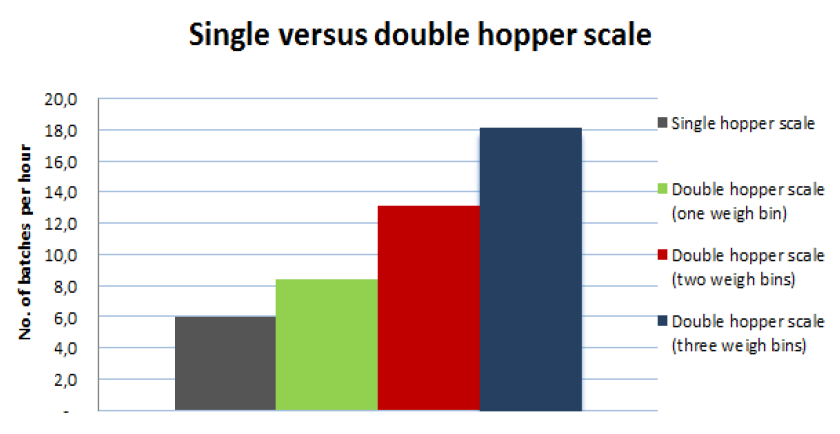

La JesHopper Doble está equipada con dos tolvas, una de pesaje y otra de carga/amlacenamiento. Esto significa que se puede iniciar una nueva carga mientras se vacía la anterior, ya que la carga, una vez pesada, se transfiere rápidamente a la tolva inferior. De este modo, aumenta significativamente su capacidad de batches por hora.

La principal diferencia entre una báscula de tolva simple y una de tolva doble es la posibilidad de iniciar el pesaje de una nueva carga antes de que se vacíe el sistema. La JesHopper Doble tiene una mayor capacidad de lotes por hora, ya que su construcción permite llenar el contenedor de pesaje mientras se vacía el lote anterior.