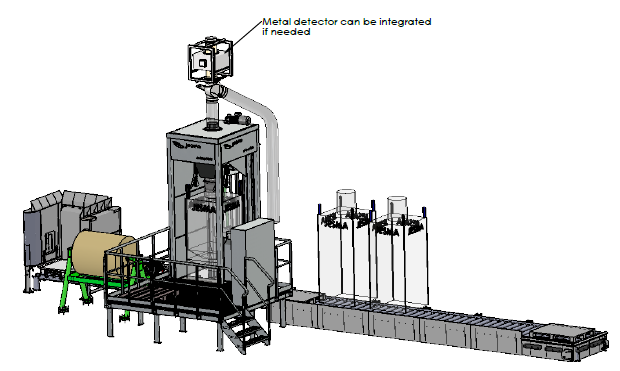

Llenado de big bags

El sistema JesBag de Jesma ofrece una buena solución para el llenado de big bags (maxi sacos), volviendo el proceso automático. Cuenta con una unidad completa para el pesaje y llenado de big bag: almacén de pallets, transportador de rodillos automático, estación de llenado con función de pesaje incorporada y un transportador de rodillos con espacio para big bag llenos.

Principio de operación:

- El pallet se librera del almacén de pallets y se detiene en la estación de llenado.

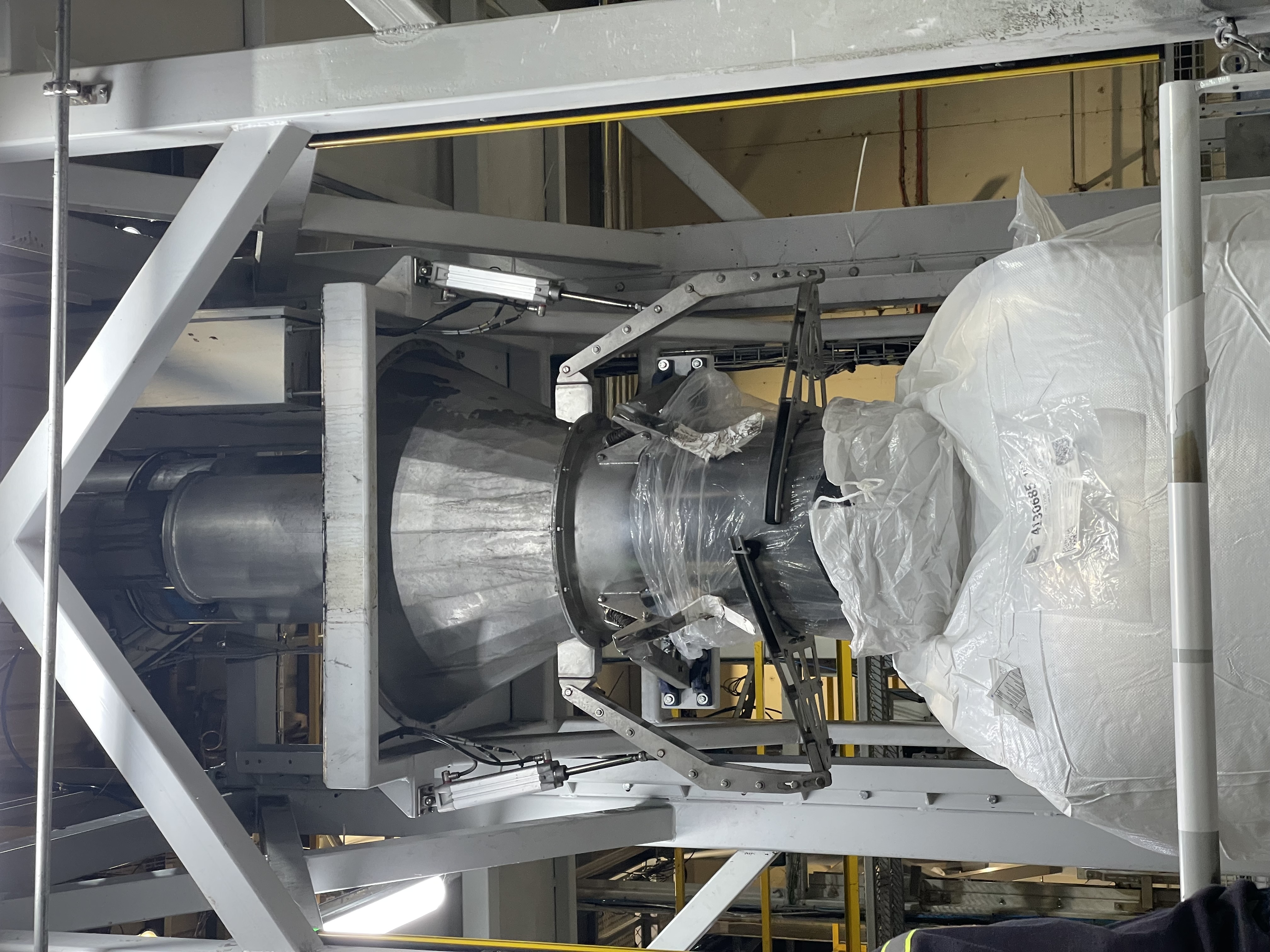

- El operador coloca las cuerdas o el cuello del big bag en los dispositivos neumáticos y el big bag se fija con una pinza al conducto de llenado

- Cuando el saco está colocado correctamente, se inicia la secuencia de llenado presionando "iniciar" en el panel de operación.

- El big bag se levanta del pallet y se infla con aire antes de llenarlo con producto.

- Cuando el saco está casi lleno, se baja de nuevo sobre el pallet y se pone en marcha el vibrador para eliminar el aire en el material. Luego se levanta nuevamente el saco y el llenado continúa hasta que se obtiene el peso requerido.

- Cuando finaliza la secuencia de pesaje, se liberan la pinza de sacos y el big bag queda sobre el pallet.

- Se puede activar el transportador de rodillos y transportar el big bag hacia adelante en el proceso y el operador está listo para un nuevo ciclo.

Dependiendo el nivel de automatización que busques, hay una solución diferente para aplicar, con varios opcionales por incluir y con diferentes sistemas de pesaje, según espacio y requerimiento.