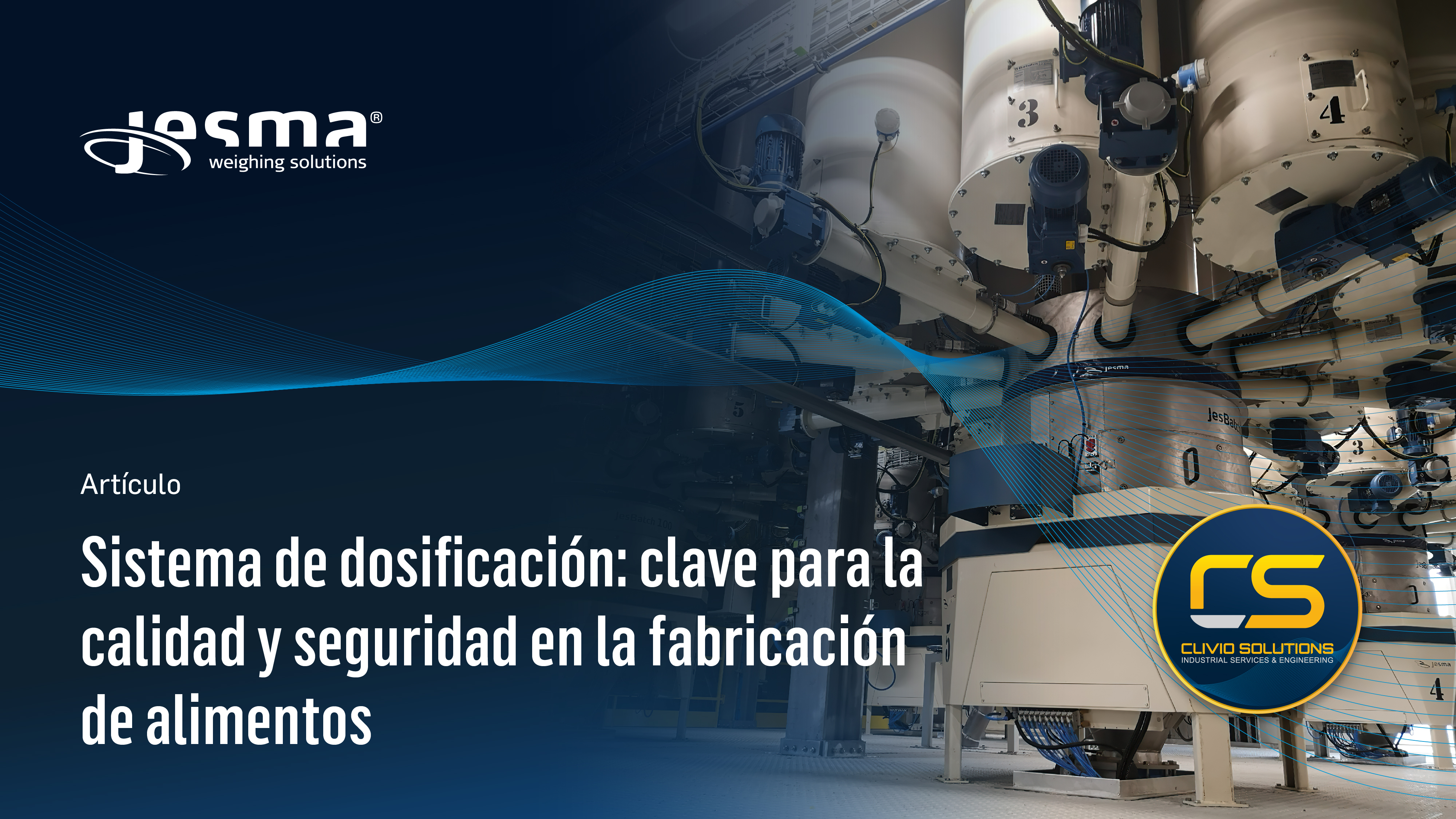

Sistema de dosificación: clave para la calidad y seguridad en la fabricación de alimentos

En la fabricación de alimentos para mascotas, peces y animales de granja, el proceso de dosificación es un pilar clave para garantizar que el producto final sea de alta calidad. Por eso, junto a nuestro partner Jesma, te presentamos este artículo con toda la información que debes conocer.

La dosificación precisa y controlada no solo asegura que cada lote de producción cumpla con los requisitos nutricionales y de formulación, sino también evita problemas de sobredosificación, lo cual puede ser altamente perjudicial para la salud de los animales, así como también la generación de costos para el fabricante.

Además de la precisión y el control, otros factores como la seguridad y la prevención de la contaminación cruzada son esenciales en los sistemas modernos de dosificación.

Contar con un sistema que minimice la dispersión de polvos no solo mejora el ambiente laboral, sino que también reduce el riesgo de explosiones, un aspecto crítico en la seguridad industrial. Y en lo que respecta a la contaminación cruzada, agregar un producto incorrecto en las formulaciones puede ocasionar graves problemas de salud en los animales.

Beneficios de los sistemas de dosificación inteligente

Los avances en tecnología de dosificación han permitido la implementación de sistemas inteligentes que ofrecen múltiples beneficios, entre los cuales destacan:

- Precisión y control superiores: garantizan que las proporciones exactas de ingredientes se integren en cada lote, reduciendo variaciones en la calidad del producto.

- Alta flexibilidad: Permiten adaptarse fácilmente a cambios en las formulaciones, optimizando la producción ante diferentes requisitos nutricionales o demandas del mercado.

- Automatización avanzada: minimizan la intervención manual, lo que no solo reduce los costos de mano de obra, sino que también mejora la consistencia y disminuye el margen de error humano.

- Inocuidad y prevención de contaminación cruzada: diseñados para operar con estrictas medidas de seguridad alimentaria, estos sistemas eliminan riesgos de contaminación entre lotes, garantizando la integridad del producto.

- Bajo mantenimiento: la tecnología moderna incorpora materiales duraderos y diseños simplificados que requieren un mantenimiento mínimo, reduciendo paradas en la producción y costos operativos.

- Fiabilidad operativa: diseñados para un rendimiento óptimo, estos sistemas aseguran un flujo continuo de operación, incluso en entornos de alta demanda.

Factores clave en la selección de un sistema de dosificación

A la hora de elegir un sistema de dosificación para una planta de alimentos para mascotas, peces y animales de granja, es importante considerar:

-

Compatibilidad con la línea de producción existente.

-

Capacidad para manejar ingredientes difíciles como polvos finos, líquidos viscosos o microingredientes, los cuales muchos de estos son de difícil fluidez.

-

Cumplimiento de normativas locales e internacionales de seguridad alimentaria.

-

Sostenibilidad energética y eficiencia operativa.

-

Sistema escalable para adaptarse a un crecimiento futuro de tu planta.

La implementación de tecnologías de dosificación de última generación no solo mejora la calidad del producto final, sino que también optimiza la rentabilidad de la operación, posicionando a los fabricantes como líderes en una industria altamente competitiva.

¿Puedes permitirte esperar para contactarnos? ¡Hazlo ahora!