¿Cómo lograr la descarga completa de los silos? ¿Tiene problemas para descargar materiales de baja fluidez?

Cuando se trata de una materia prima de difícil fluidez, la descarga de los silos se vuelve un problema. Por ejemplo, materiales como las harinas de origen animal, expeller de soja o pellets con presencia de finos, son casos donde la fluidez es muy baja, por lo que en la mayoría de los casos los operarios deben ingresar a los silos para lograr el vaciamiento completo de los mismos, poniendo en riesgo su seguridad. Es habitual escuchar que los operarios ingresan a palear los silos o golpearlos por fuera para descargar las materias primas. Esto dejará de ser un problema con la instalación de Descargadores de Silos que ofrecemos en Clivio Solutions, equipos flexibles, resistentes y confiables en el manejo de todo tipo de materiales, especialmente los de difícil fluidez.

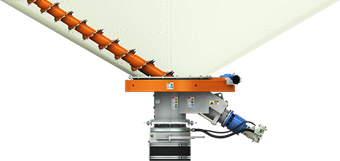

Los sistemas cuentan con un tornillo que gira sobre su eje y a su vez rota en toda la circunferencia, tanto en los silos de fondo plano como en los cónicos. Con la instalación de estos equipos obtendrá numerosos beneficios:

- SEGURIDAD: Evitar poner en riesgo la vida de los operarios

- INOCUIDAD: Evitar el estancamiento de los productos (rat holing) que podrían generar microorganismos no deseados, afectando la calidad del alimento

- TRAZABILIDAD: Asegurar la trazabilidad logrando que lo primero que entra es lo primero que sale (FIFO)

- CAPACIDAD: Asegurar el llenado y vaciado completo de los silos, aprovechando su máxima capacidad

En el siguiente video se puede observar la descarga de un silo de fondo cónico y plano con el Descargador de Silos y su comparación con un sistema convencional: www.youtube.com/embed/dJ4152lvzAg

Si le interesa saber más del tema no dude en ponerse en contacto.